A Hundred Years of Engineering Craftsmanship 1857 - 1957

Despite their

considerable success with steam engines Tangyes were ever vigorous in exploring

new fields. The high standards of engineering craftsmanship throughout the

works enabled them to undertake new lines of production and keep well abreast

of the latest developments. Between 1880 and 1900, therefore, Tangyes established themselves as

manufacturers of gas and oil engines. This early start with the internal

combustion engine was due partly to foresight and partly to good fortune in

finding another inventor to rank in the Company’s annals with Weston and

Cameron.

Although experiments with gas engines had been conducted in Europe and America

over a number of years, it was not until Dr. N. A. Otto built his successful

Silent Gas Engine in 1876 that the engine became a practical manufacturing

proposition. Otto had worked for twenty years before he produced the engine

which was sufficiently economical and efficient to make the internal combustion

engine a valuable prime mover — potentially as important to industrial history

as the steam engine.

Adopting a system advocated by Beau de Rochas in 1862, Otto had worked out a

four-stroke cycle with a good form of flame ignition, the compression and

explosion of the gas and air mixture taking place within the one cylinder.

While Crossleys of Manchester obtained the licence to manufacture the Otto in

Great Britain

rival designs were being rapidly developed, especially in the two-stroke field.

The latter part of the ‘seventies was consequently a period of great excitement

with new gas engines appearing every year. Of these the best-known was probably

the two-stroke engine of Dugald Clerk which he patented in 1878. The main

feature of this engine was a separate pump which compressed the gas and air

mixture into a reservoir. The mixture was then admitted to the power cylinder

and ignited during the first part of its stroke, exhaust gases being removed on

the return stroke. This patent was superseded in 1881 by an engine in which the

pump was used only as a displacer, the mixture entering the cylinder at about

lb. per square inch above atmospheric pressure; the entering charge displaced

the exhaust gases by way of ports overrun by the piston.

Meanwhile Tangyes were actively searching for a machine already perfected in

design and suitable for manufacture in quantity. Various paper inventions had

already been rejected when in April 1879 Gentle, of the London Office, saw H.

Woolfe ‘re Gas Engine’ and arranged for one to be sent to Soho. This must have

proved a failure for in the autumn the firm opened negotiations with Frederick

Hurd, Engineer, of Edinburgh and Wakefield, for the

exclusive licence to manufacture his Patent Silent Gas Engine. For several

weeks Hurd was hesitant about terms and although in November he forwarded

several orders he had still not produced his sample 6 horse-power engine.

A more promising agreement was next made with Horace Robinson of Manchester, who took Out

a patent in June 1880 entitled ‘Improvements in Gas Motor Engines’. Tangyes

undertook to make this engine and Robinson was to come to Soho to supervise the manufacture.

George Tangye pressed him to send his prototype

at the earliest convenience. Robinson, however, was as dilatory as Hurd and by

December 188o his drawings for the engine had still not appeared.

Frustrated on two counts Tangyes now met a man whose work on the gas engine was

fundamental and of long standing. This was not known to them when, in December

1880, George Haswell wrote to James Robson about a direct-acting pump to be

driven by gas as that is an apparatus which would, I have every reason to suppose, be

useful in many special cases where steam or air are not available. I would be

glad to know if you have made one of these pumps, and if so where it could be

seen.’

Haswell

and Robson, both natives of North Shields, seem to have met during the

Christmas holiday, for on 4thJanuary, 1881, Robson signed an agreement giving

Tangyes sole right for the manufacture of his gas-operated pump and gas hammer.

The patent of 1880 which covered the pump and hammer also included an engine

designed on the spring-type atmospheric pressure principle. R. Waygood &

Co., of London, had already begun manufacture of this engine which was exhibited as the London

Gas Engine at the London Cattle Show in 1880. Soon after he had signed his

agreement with Tangyes, Robson brought them two earlier patents which covered a

different type of gas engine of the kind for which they had long been

searching.

The value and originality of Robson’s work on the development of the internal

combustion engine has been comparatively neglected for he was a man who sought

no fame for himself nor publicity for his work. James Robson was born in North

Shields in 1833, son of James Robson, builder and contractor. His lifelong

study of problems of internal combustion began quite accidentally. On his

return from a visit to the Great Exhibition of 1851, he set out to construct an

incubator similar to one which he had seen exhibited. Using, for convenience, town

gas instead of paraffin, he soon discovered the explosive nature of a gas and

air mixture. He was immediately diverted from his original purpose to an

investigation of the pressures exerted on a small closed cylinder— 24 in. long

and 3 in. diameter — by the ignition of mixtures of gas and air in various

proportions. The maximum

pressure which he obtained was between 6o and 70 lb. per sq. in. By 1857 Robson

had built his first gas engine working on the direct-explosive atmospheric

principle with an explosion at every revolution of the crankshaft. Designed

entirely for experiment this engine furnished Robson with experience and

information on which to base his plans for larger working engines. He spent,

for example, some time on developing various systems of ignition.

Robson’s second engine was soon built in 1858-9. It was of three horse-power

and was set to work driving a circular saw in his father’s workshop, where it

was successfully employed, until frost burst the water jacket. Two more engines

of similar design were also installed in North Shields; one for driving the

printing machinery at the offices of the Shields Daily .News and the

other — of one horse-power — at Simpson & Mustard’s Printing Works. These

working engines establish Robson among the earliest pioneers of the internal

combustion engine.

Although the designs incorporated several important features, such as cooling

of the working cylinder by a water jacket and ignition by an electric spark,

Robson took out no patents. His interests were now absorbed by the possibility

of compressing the gases before ignition in order to improve the efficiency of

the earlier engine. Unfortunately at this vital stage his experiments were

interrupted; first, by the destruction of his workshop and experimental engine

when the gable end of his ironmongery shop collapsed during excavations on the

adjoining land. And secondly, by the death of his uncle which made it necessary

for him to help his father with the building and quarry business in North

Shields. Nothing, however, could quell Robson’s enthusiasm for the gas engine.

He was soon at work on a vacuum type of engine. This was followed by his

Vertical Spring-Type Atmospheric Engine, later revived and included in the 1880 patent. From these he moved to

his most important invention the ‘two-cycle’ gas engine. The first patent,

which he took out in 1877, clearly shows Robson to have been the first to

design a two-cycle engine, giving an impulse at every revolution of the

crankshaft, in which compression was performed in the same cylinder as

ignition, combustion and expulsion of the gases. Other two-cycle engines, like

Dugald Clerk’s, had used a separate pump for compression and for charging the

motor cylinder. Only the four-cycle engines of Otto’s design, giving an impulse

for every two revolutions of the crankshaft, had previously compressed the

mixture in the cylinder.

Robson improved the design and obtained a second patent for his two-cycle

engine in 1879. This was the engine which he brought to Tangyes in 1881. An

arrangement was quickly made between Tangyes, Robson and Messrs. Waygood &

Co., giving to both companies equal rights to manufacture Robson’s engine and

Robinson’s engine, the patent of which was now owned by Tangyes. Tangyes

immediately concentrated upon Robson’s two-cycle engine and Robinson’s patents

were allowed to lapse in 1885.

Knowledge and experience of gas-engine problems was still very limited, but the

Robson engine enabled the firm to make an early and successful start with the

internal combustion engine at a vital stage in its commercial development. The

Robson engine was exhibited for the British Association Meeting in Birmingham in 1886. The

first size, was a one horse-power engine built on the Tangye steam engine bed.

Later half, two-and-a-half and four horse-power sizes were made. About 300 Robson engines were sent

out from Cornwall Works to various markets, including Denmark, Sweden, Spain, New Zealand and Australia.

While Robson concentrated upon the gas engine his other inventions were put on

one side. Eventually he returned to work on the Gas Forging Hammer, and by 1884

it was ready to be put into production. The first of its kind, it attracted

considerable attention when first exhibited the next year. Although sales were

limited — partly because of prevailing trade depression — credit is due to the

skill and workmanship which made its development possible.

Throughout these years trials were also being made at Cornwall Works with

various other types of gas engine. In 1886-7 Tangyes began building Clerk’s

patent two-stroke gas engines. Meanwhile a new four-stroke engine was designed

by Charles W. Pinkney, who had been with the firm since 1876. Working closely

with Robson on his gas engine, and responsible for considerable improvements in

the design of the gas hammer, Pinkney’s inventiveness and experience made him

extremely valuable to Tangyes in these years. He was soon given charge of the

gas engine ‘sheds’ and his opinion was relied upon for the assessment of new

gas-engine inventions submitted to the firm.

Pinkney’s gas engine was ready by 1889 and in running was found to be slightly

more economical than the ‘Otto’. The ‘Otto’ patent, however, was by this time

rapidly running out and it was eventually decided in the Spring of 1891 to

start manufacturing a four-cycle engine on the ‘Otto’ principle rather than to

proceed with the unknown Pinkney model. Soho engines built on this plan brought a large increase in trade and soon

extensions to the gas-engine department became necessary. Governed on the

hit-and-miss principle, these engines produced that irregular running beat

which was at one time so familiar. Many of them gave exceptionally long

periods of service and some are still at work in Birmingham.

The value and use of the gas engine was greatly extended by the. introduction

of the gas producer. As early as 1893 Tangyes investigated the possibilities of

the ‘Blum’ Gas Producer, but decided not to start manufacture at that period.

The following year Pinkney designed a ‘Hydro-carbon Gas Producer’, which was

also laid aside. Not until 1905 was

a gas producer introduced as part of the regular output at Cornwall Works. This

was a ‘suction’ gas producer designed to work on three types of fuel; hard

coals: soft fuels like bituminous coals and lignite; and vegetable fuels such

as wood waste, sawdust, or anything combustible which the neighbourhood might

have to offer.

The versatility of this gas producer widened the potential market for the gas

engine both by reducing the cost of fuel and by enabling the engines to be used

well away from a source of town’s gas. During the following twenty-five

years large numbers of producers were made and the firm acquired great

experience in their design and application. Many are still in use.

Apart

from water-power, the gas producer in conjunction with the gas engine, gave the

cheapest power in the world. In 1906 it was calculated that the suction gas

producer using anthracite would develop 10 to 20 B.H.P. for a penny an hour. This was ideal for small

concerns where power was required, and was an equally good investment for those

dependent on erratic water supplies such as the Welsh woollen mills in the

lower valleys.

On the heels of the gas engine, and as the natural development, came petroleum

and oil engines. The Priestman paraffin or kerosene engines exhibited between

1885 and 1890; the work of Akroyd Stuart with heavy oil engines, which produced

the Hornsby-Akroyd engine in 1894; and the first Diesel engine built by the

Augsburg Company in 1897, were the major landmarks in this development which

brought oil engines to the forefront in industrial development and

mechanization.

Alongside his gas engine Pinkney was developing in the late ‘eighties a

petroleum engine which he patented in 1891. This was the refined petroleum

engine which Tangyes introduced in 1892. Work on these engines intensified as

years went by — they were a strong selling line in many home and foreign

markets.

A portable oil engine of Pinkney’s design was shown at the Royal Agricultural

Show of 1898. This engine, which developed 6 B.H.P.,incorporated an unusual arrangement for cooling the

water:

The engine draws the water out of a tank that forms its base, and forces it through the cylinder jacket

and thence through a pipe from the top of the cylinder, on to a canopy, where

the water is split up and cooled while being exposed to the atmosphere. The

water next passes on to the roof of the carriage where it is collected and

allowed to drain back into the base or tank of the engine, and used over again.

Greater success was achieved by a new, lighter, and less expensive paraffin

engine especially designed for agriculture which made its appearance some ten

years later.

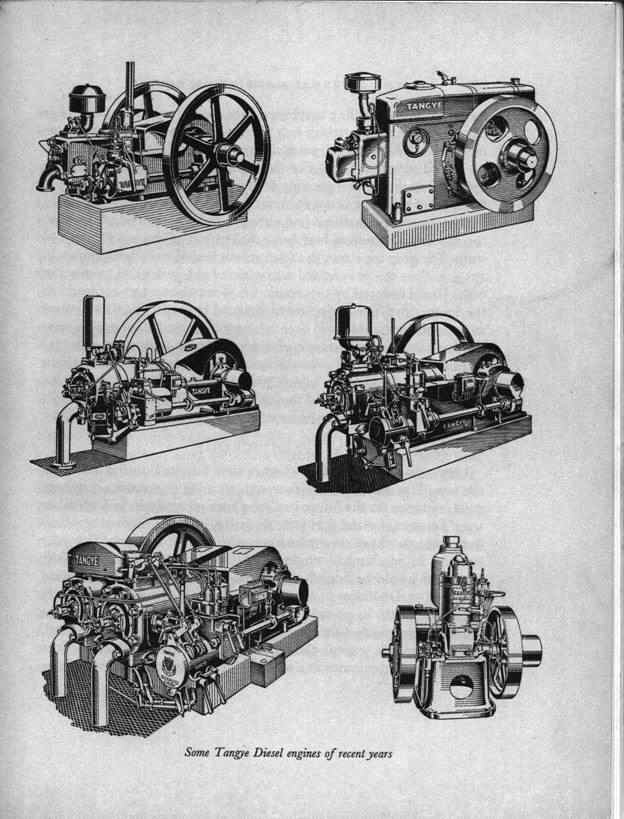

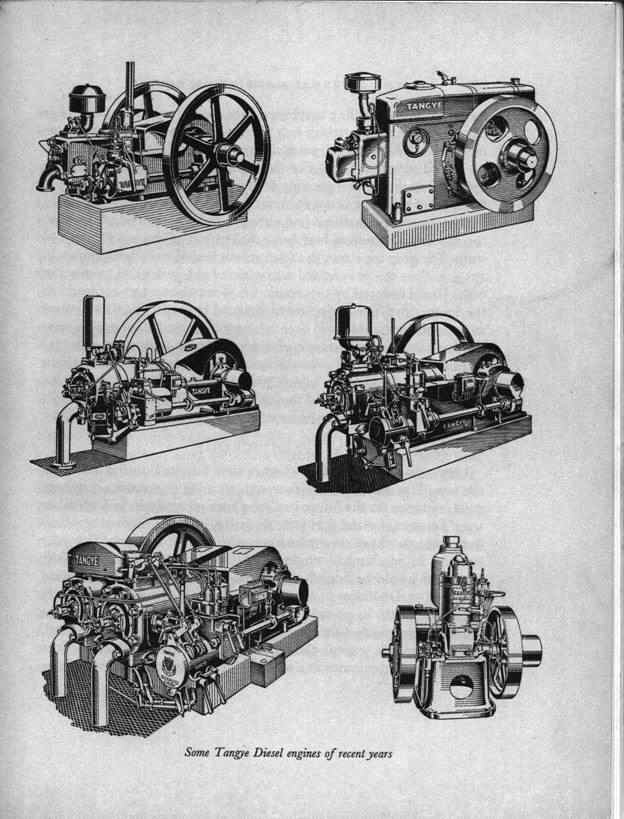

In 1910 Tangyes

introduced a range of engines running on crude oil. These engines were of the

semi-diesel type using blow-lamp heating for starting. The disadvantages of

this system were overcome by the introduction in 1916 of a cold-starting oil

engine. This engine started on petroleum and then turned over to the oil which

it used as fuel. It was the immediate fore-runner of the present-day

compression ignition engine which Tangyes began to make in 1920. This engine, which ran on

a wide range of low-grade oils, was of a sturdy horizontal design and proved

extremely popular for many overseas markets. Its ability to stand up to

unskilled attention made it especially popular in Eastern countries where it

was widely used in agriculture, for drainage and irrigation. Manufacture of a

modern version of this engine still continues at Cornwall Works; general

production of gas engines, however, ceased in 1939.

In the years between the end of the nineteenth century and the outbreak of the

First World War, the foundations of the present age were laid not only in such

applied scientific developments as the internal combustion engine, but also by

increasing government activity

in social welfare. Public Health Acts administered by new local authorities,

for example, made essential the construction of many large waterworks and

sewage disposal schemes. The war accelerated these public health measures in

many areas. Throughout the period Tangyes obtained many valuable contracts for

this type of work at home and abroad. As manufacturers of a considerable range

both of engines and pumps, they were particularly well placed to carry out

complete installations. According to the requirements of the job, pumps of

almost any type could be coupled with steam, gas or oil engines and serviced as

a unit — facilities which very few competitors could equal.

Many of these plants are still giving excellent service and stand as a tribute

to Tangye reliability. Two such installations which have been in use for over

thirty years, are those designed and engineered in 1924 for the Leicester Corporation and the Mid-Kent Water

Company. The first was one of the largest pumping plants ever built by Tangyes:

at the time the three 36 in. stroke Treble Ram Pumps, each weighing about 100

tons, were the largest of their kind in the country. They are still giving

eighteen hours of trouble-free running every day. The second consisted of a

pair of large deep-well pumps driven by oil engines. These, too, are still

eminently satisfactory for their daily work and, moreover, cost less to run

than many more recent plants.