CORNISH BACKGROUND

The name Tangye itself betrays that Cornish origin proudly proclaimed in the

title ‘Cornwall Works’ and by the adoption of the County arms for trade mark.

The founders of the firm were indeed loyal Cornishmen trained in one of the

foremost engineering areas of the British Isles; for Cornwall a hundred years ago was renowned not

so much for its coastal beauties as for its mines, its foundries and its ports.

Bleak and inaccessible, except by sea, the Cornish peninsula had long supported

an inventive and independent breed of men subsisting upon their own skill and

resources. ‘Fish, tin and copper’ was a familiar toast among those who wrested

their livelihood from land and sea.

Around Camborne and Redruth lay the important mining areas where the land,

heavily scarred by the labour of generations of mineworkers searching for tin

and copper, was spiked with the tall chimneys of the engine-houses. The mines,

threatened with extinction in the middle of the eighteenth century, when the

Newcomen engines could no longer pump the deeper workings free of water, had been

saved by the arrival of the Watt steam engines from Soho.

James Watt first came to Cornwall in August 1777 to supervise the installation of

his great pumping engine at Wheal Busy. Somewhat disgruntled after five days’ hard

travelling in chaise and diligence, he wrote to Matthew Boulton at Soho

‘The people here have the most ungracious

manners of any people I was ever among’ and ‘In general the Engines here are

clumsy and nasty, the houses crackt, and everything dripping with water from

their house cisterns’.

Despite considerable hostility to the ‘foreigners’

from ‘up country’, the reputation of the Watt engines, which almost doubled the

depth at which the mines could work, was soon established, and orders became so

numerous that the firm sent William Murdock to Redruth to supervise the

installation and maintenance of all the engines in the area. Murdock — a man of

great originality and inventive genius — remained throughout his life a trusted

and loyal servant of the firm of Boulton and Watt. It was while he was in

Redruth (between 1779 and 1798) that he worked out the sun and planet motion,

immediately adopted by Watt as an alternative to the patented crankshaft, built

a model steam road locomotive which he demonstrated in the lanes near his home,

and successfully experimented with the use of coal gas for house illumination.

In response to the demands of the mining areas grew up the great foundries —

Hayle (1770) and Perran (1791) among the first, and later Copperhouse (1806),

Redruth, and James Holman of Pool (1839). Here men worked on the boilers, pumps

and castings which the mines and the engineers constantly required in the

struggle for greater production. Among the foundries and the mines young

Cornishmen developed their mechanical skill and their quickness to produce new

ideas. Many reached the front rank in engineering; of these probably the most

famous and original was Richard Trevithick (1771-1833), whose father was

captain of the great Dolcoath Mine. Trevithick was born, like the Tangye brothers

later, in Illogan. Possessed of outstanding physical strength and presence in

addition to his mechanical inventiveness, he remained a legend in the county

for more than a generation.

Until Watt’s patent for the separate condenser expired in 1800, Trevithick

found himself constantly ranged against the Boulton and Watt firm who made

every effort to restrain his activities, but as soon as he was released from

these restrictions he forged ahead with his high-pressure engine. About thirty

of these ‘puffers’ were installed to wind up ore from the mines. He then used

the engine in a steam road locomotive, which carried passengers for the first

time on Christmas Eve, 1801. Trevithick was indeed ready to apply the

engine to almost any work — to a tramway in Penydaran in South Wales, to an

experimental steamboat, or to agricultural machines.

But his temperament was not suited to the commercial development of his ideas

and in 1816 he sought to retrieve his fortunes by setting off to install his

engines in the mines of Peru.

The revolutionary wars brought a disastrous end to this adventure and

Trevithick returned penniless to Cornwall in 1827. On his way home, at Cartagena in

Colombia, he had met Robert Stephenson, who gave him £50 towards his passage. Stephenson was

himself returning from an engagement with the Colombian Mining .Association to

help his father with the projected Stockton and Darlington railway.

It was the eve of the Railway Age.

The building of railways brought engineers to many of the quietest towns and

villages of rural England,

where the locomotive steam engine rapidly became almost a commonplace. To the

West Country came Isambard Kingdom Brunel, as engineer to the Great Western and

to the South Devon and Cornwall railways. Already well known for his work on the Thames tunnel, and for his

elegant design for the unfinished Clifton Suspension Bridge, Brunel adopted

various revolutionary schemes for his new task: he decided to use the broad

gauge on the Great Western contrary to all the rival railway companies; in

South Devon he laid down an atmospheric railway (which proved a failure); at

Box he constructed the longest tunnel of his day, and he built hundreds of

bridges — culminating at the end of his life in the great Saltash Bridge.

During the same period he designed and supervised the construction of the huge

iron ships — the Great Western, the Great Britain and the Great Eastern.

Leading engineers at this time set no arbitrary limits

to their field of activity. Their powers and achievements ranged widely over

civil, mechanical and marine engineering. New tools, new methods, new

inventions appeared everywhere; engines were releasing men from centuries of

drudgery and transforming the productive potential of industry; railways were

altering the social and economic conditions of the world. Against this

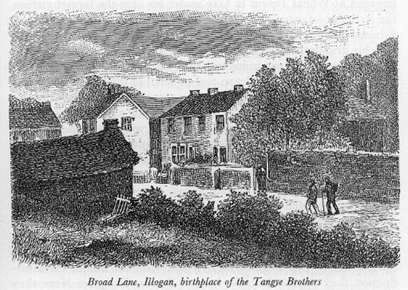

background between 1825 and 1835 were born in Illogan the nine children of

Joseph and Ann Tangyc. How five of these children were caught up in the great

engineering industry and what they achieved is the story of this book.

THE FAMILY

Illogan lies, a straggling village, between Redruth and the Atlantic.

Through it ran an early single track railway carrying ore to the small but flourishing

harbour of Portreath. In the shadow of the ancient

height of Cam Brea, surrounded by the activity of the mines, and swept by the

free winds of the Atlantic there was much to inspire a growing family with

independence and determination. But long before the outside world and its

excitements could affect them, the foundations of the careers of the six boys

and three girls were laid in happy, disciplined, and religious home

surroundings.Joseph and Ann Tangye were members of the Society of Friends, and

on Sundays the whole family set out for Meeting at Redruth two miles distant, ‘the youngest two and two and hand in hand,

with father and mother coming last’.

From their faith sprang that spirit of service for others and strong

self-discipline which marked their home life in Illogan, and the perseverance,

hard work, moral courage and philanthropy variously displayed by the brothers

in later life.

The youngest son, George, vividly remembered his childhood over more than half

a century and wrote some account of it. He recorded that his father, Joseph

Tangye, was a small coal merchant and also ‘kept the modest store, or village

shop, where everything was sold that could be wanted by the country round —

drapery, groceries, crockery and general haberdashery, and also a little stock

of homely medicines. We lived on a pretty little farm whence the family drew

all that a farm could produce — not omitting a plentiful supply of lovely

Cornish cream’. Of his mother George wrote: ‘No woman gave up her whole life more for her family and for those

around her.

|

|

She was my father’s right hand, and

more — for she managed the business and kept the accounts. Many of the poor

miners could only pay when they received their wages,which was only once a

month, but none of the dear old customers was sent away empty. My parents often

came between them and the workhouse and when pay day came they did the best

they could.

To their maternal grandfather, Edward Bullock, the boys, especially the two

eldest, James (born 1825) and Joseph (born 1826), owed their introduction to

the engines and the smithies of the nearby mines. Born further east in 1776,

the year before the first Watt engine arrived in Cornwall, Edward Bullock had migrated as a

youth to Illogan. He soon became a practical engineer and as such was engaged

at Wheal Tolgus to take under his care the largest engine, the cylinder of

which had a diameter of 86 in. Like Trevithick, Edward Bullock had been widely

renowned for his feats of strength and his grandsons remembered him as an

imposing and powerful figure.

He took the boys to his own little smithy and

workshop, where they delighted to help, to learn and to listen to the stories

of engines and engineers with which the old man entertained them. They were

soon promoted to a workshop of their own, and spent all their spare time

learning to carry out repairs, to build working models and to make their own

tools, eventually their own lathe. The knowledge and experience they gained in

this way — and the lathe itself— was of infinite value to them in later life.

|

When the time

came for James to leave his father decided to place him at one of the large

foundries, where he could develop his obvious interest in engineering. Armed

with an influential introduction they approached the famous Perran Foundry.

Here they were disappointed but met with more success at the Copperhouse

Foundry at Hayle where James was taken on as a ‘molliwig’, the boy at

everyone’s beck and call. At Copperhouse James became acquainted with the use

of hydraulic power — later the foundation of the family firm — and he also saw

for the first time the great Brunel, who visited the foundry to see the plates

being tested for the Clifton Suspension Bridge. The first work on this bridge

was undertaken between 1836 and 1843 — when lack of funds halted the project

for twenty years — so that James must have been at the foundry during part of

this time.

Variety of working experience was the essence of James’s training, and before

long he left the foundry to join a local wheelwright with the immediate object

of learning to make a tricycle. Here skill and application soon made him

proficient at all kinds of wheelmaking and he turned the knowledge to good use

on his father’s farm. About this time he also designed and built a waterwheel,

18 ft. in diameter with 20 in. breast, for a nearby stamping mill.

Soon James came to the notice of William Brunton, senior, who had been one of

Brunel’s engineering assistants and who together with his son, played an

important part in the lives of the young James and Joseph. James’s first work

for Brunton was helping to install a new method of ‘dressing’ tin in the mines.

Shortly afterwards Brunton employed James in his private workshop to make some

hydraulic pumps. In this workshop was a Holtzapffel lathe, the most beautiful

precision tool of the period, upon which Joseph learnt to perform miracles of

craftsmanship.

Still seeking new knowledge and instruction, James left Brunton for the Redruth

Foundry. He spent a year there before moving on to Distin and Chafe, general

engineers, of Devonport. Although under twenty he astonished many by his

knowledge of beam engines

— he and Joseph had constructed a working model at Illogan — and he was soon

earning a substantial wage. Trade depression brought him back home and he

joined William Brunton, junior, in making machinery for the manufacture of

safety-fuse for blasting purposes. Brunton was using gutta-percha, still a very

new article of commerce in the experimental period of development, to cover

fuse for Sir John Franklin’s polar expedition which sailed in May 1845. Joseph

was already working on the safety-fuse. He and James had always worked most

successfully in harness and from this time they were almost constantly

together. Joseph’s training had been very similar to James’s. On leaving school

he was employed at Camborne atJohn Holman’s works,which had opened in 1839.

While James was with his wheelwright, Joseph joined a local blacksmith and

thoroughly mastered all the details of smithing. It was during this period that

these two constructed in their own workshop their model steam engine with

parallel motion and reversing gear, complete with Cornish boiler. James and

Joseph were next together for a time at the Redruth foundry, where Joseph’s

skill was displayed on the largest lathe. After a period of rest to recover

from threatened ill-health, Joseph followed James to Plymouth and was employed on the manufacture

of the first match-making machinery ordered by Bryant and May. Later he

returned to William Brunton, junior, where he was soon rejoined by James. Here

they both remained for many years, making all the machinery, and eventually

became the working managers.

|

|

|

Richard was promoted to Sidcot in February 1847, and George in October 1848.

After two years’ study, Richard was apprenticed as a junior teacher — he was

fifteen-and-a-half years old. Unfortunately the work proved uncongenial,

despite much kindness from colleagues and from the Friends, and after three

years he applied for his indentures to be cancelled. When this was finally

arranged, at the beginning of the summer vacation 1852, Richard was ready to

take the plunge into the world of commerce. In answer to an advertisement in

the British Friend, he applied for and obtained a position as clerk at

the works of Thomas Worsdell in Birmingham.

George meanwhile had left Sidcot in 1850 and joined his eldest brothers in

William Brunton’s safety-fuse works, where in the office he learnt ‘the secrets

of bookkeeping by double entry’. He then moved to Lord Clifden’s estate office

where his brother John had worked. It was not long, however, before Richard’s

enthusiasm for his new surroundings encouraged George to leave Cornwall and join him in Birmingham.

ARRIVAL IN BIRMINGHAM

Off Broad Street, among many of the small factories which have for so long been

characteristic of Birmingham,were Thomas Worsdell’s factory in Berkely Street,

and his railway wagon works in Tennant Street. He

traded as railway wagon builder, machinist and manufacturer of lifting jacks,

screwjacks and presses, lathes, drill and other machines; steam engine builder

and railway store contractor. Next door among japanners and manufacturers of

telegraph wire and gas fittings, were the Suffolk works of John Eliot Hodgkin,

engineer and ironfounder, where Richard had obtained a post for his brother as

clerk of the works.

On 7th September, 1853 Richard, now in his twentieth year, met George, two

years younger, at the Lawley Street terminus of the Midland Railway.

Half-a-century later George wrote, ‘I well remember the evening of my arrival

in the great town. I knew no one there but Richard, who piloted me to the new

lodgings he had taken in Bath Row, a man taking my luggage on a wheelbarrow. We

had a comfortable sitting-room and one large bedroom, for which we paid so much

per week, providing ourselves with eatables, which were cooked for us by our

good landlady, Mrs. Fulford. In the evening Richard told me that he had purchased

a load of coals, for which we owed thirty shillings. Fortunately, I had a

little more than this left, and it was used to settle the coal bill. I then had

about one shilling and sixpence left to begin life with in Birmingham, and from

that day to this I have never felt the want of money to provide for all I

needed’.

|

|

From the first in fact, Richard and George were not entirely without friends

for they brought introductions from home to many Quakers in Birmingham, who extended a warm welcome.

George was placed under the ‘loving guardianship’ of Mrs. Charles Sturge, and

on his first Sunday accompanied Richard to the Severn Street Adult School,

founded by Joseph Sturge in 1845. George was soon put in charge of the library,

and within a few weeks was given a new assistant —Joseph Sturge, junior, aged

six. The Adult Schools, held on Sundays, taught reading and writing, combined

with some biblical instruction, and were one of the greatest contributions of

the Quakers to nineteenth-century education. George Tangye was associated with

this work for the rest of his life, and succeeded in opening at the Cornwall

Works in 1877 a branch of the School over which he presided as superintendent. |

Such a room was found at ’40 1/2 Mount Street’, off the Parade, at a rent of four

shillings a week. Like many small workshops in Birmingham even today, it was approached

through an alley between houses. Power was provided by a belt from a steam

engine next door, but was of course only available when the engine was running

— a factor over which the tenants had no control. It was warmed by a nearby

baker’s oven. Here Joseph, with his excellent workmanship and his fine

home-made lathe, laid the earliest foundations of the Cornwall Works and of the

Tangye tradition.

THE PARTNERSHIP - JAMES TANGYE AND BROTHERS

Joseph soon made a success of the workshop, being able, George later recorded,

‘without too much regard for hours’ and when orders were forthcoming to earn

from twenty shillings to forty shillings a day — a considerable amount when the

average salary of a clerk or a skilled foreman was around £100 a year. James,

whose mind was clearly preoccupied with problems of hydraulics at this time,

soon decided to join Joseph in Mount Street and after due notice left Worsdell and

Evans on good terms with masters and men. The workmen indeed held him in such

esteem that they presented him with a set of tools which he continued to use

with pride during the rest of his life.

Since Richard had left Worsdell’s he had been trying to work up a connection as

a general merchant on his own account. With no capital to buy or rent premises

he was considerably assisted by two well-known local Friends, William White and

Cornelius Pike, who allowed him to operate from their booksellers’ shop in Bull

Street. His progress in trade had not, however, been outstanding and for some

time he was dependent on his brothers with whom he lived. He now abandoned the

merchanting business and took to a desk in the small workshop in Mount Street.

His position for the first few years, when he was mainly concerned with seeking

orders, was almost supernumerary, but his office training became of first

importance once the business began its rapid expansion.

George, promoted to the management of the works, continued at Worsdell and

Evans for some time — his regular income being a valuable asset to the

brotherhood. But on his return from a short holiday forced upon him by overwork

and illness, he was handed his notice by Evans. The Mount Street workshop could scarcely

support another at this time and George was fortunate to obtain employment with

the old family friends, Brunton & Co., as salesman for their safety fuse.

While travelling on his employers’ business he was also able to canvass for

orders for James and Joseph with success on both accounts. All his spare time

in Birmingham he spent at the workshop in which the four brothers’ already felt

their futures were involved. With their sisters, who had left Cornwall after the

death of their parents, they were all living together except for Edward whom they

now invited to join them. Edward, still in America, immediately accepted their offer

and after a six weeks’ voyage was warmly welcomed in the new home.

Thus in 1857 the five brothers together formed their

first company under the name of ‘James Tangye and Brothers’.

Working as ‘engineers and machinists’ they concentrated upon hydraulic and

other lifting jacks. Although of necessity many special orders had to be

undertaken in the earliest years, Tangyes aimed to build up their trade in

certain lines which could be made for stock. Few of their contemporaries

adopted this policy and therefore always ran the risk of being left with work

undertaken in special sizes or particulars for which there was no other demand.

This important principle of manufacturing stock lines, combined with

considerable acumen in developing new projects closely in accord with the needs

of industry, lay at the root of much of the financial success and stability of

the firm. It is, for example, a great tribute to the engineering skill and the

perspicacity of its original members that the firm is still in the front rank

with its hydraulic lifting devices, the work on which the enterprise was

founded.

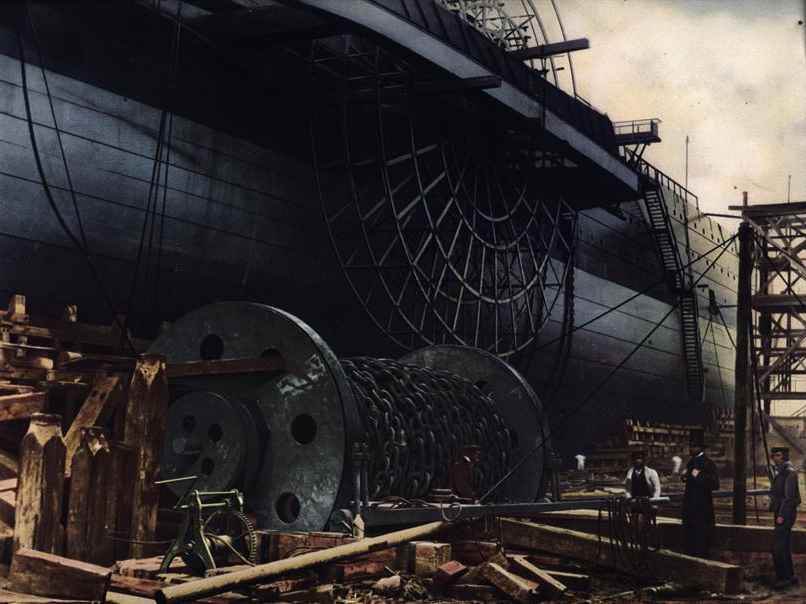

LAUNCH OF THE GREAT EASTERN

Reproduction of a contemporary photograph with modern colouring,

taken during the preparation for the launch. John Scott Russell, her builder, stands on the

right.

The theory of hydraulic power formulated by Pascal

was practically applied by Bramah at the end of the eighteenth century, and

many Bramah ship jacks later came to Tangyes for repair. More general use of

hydraulic power for the multiplication of human effort was only slowly

demonstrated in the first half of the nineteenth century when it was mainly

used for testing chains, anchor cables and plates. Most spectacularly in the

1840’s hydraulic power had been used to raise the great tubes of the Britannia

Bridge across the Menai Straits. In the

same decade Sir William Armstrong began his important investigations on

hydraulic devices and obtained in 1846 his first patent for ‘apparatus for

lifting, lowering and hauling’, which he soon developed into his hydraulic

crane. At the Great Exhibition in 1851 Armstrong exhibited models of his

various hydraulic works. Among other exhibitors a few showed hydraulic rams,

jacks and presses, but in the main hydraulic work of this kind was clearly a

new development offering wide scope for the intelligent engineer and

manufacturer.

The first Tangye patent specification of 24th March, 1857, shows the lines

along which James and Joseph were then working. The application describes an

improved hydraulic jack which ‘Consists

of a cylinder open at both ends and closed in the middle. The ram or piston of

the jack is stationary, and is fixed on the base of the instrument. One of the

compartments of the cylinder fits and rises upon the said piston. The upper

Compartment of the said cylinder constitutes a reservoir from which the liquid

is transferred by means of a pump to the lower cylinder, the said cylinder

being thereby raised. The inventor prefers to employ oil instead of water in

the improved jack’.

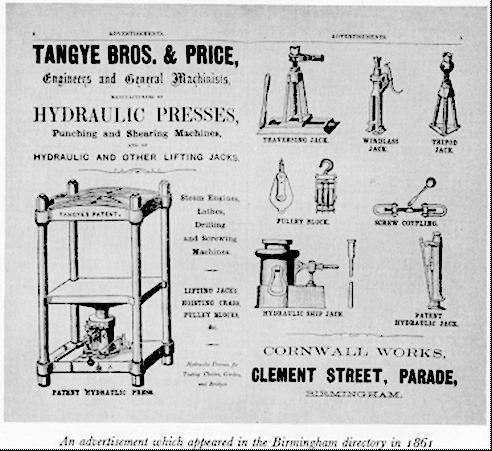

This jack seems to accord with the patent hydraulic jack illustrated in the

firm’s advertisement in the Birmingham Corporation Directory for 1861.

After a few months the workshop proved too small for all the work which the

brothers felt they could undertake. In October 1857 they rented, for ten

shillings a week, a larger workshop at the same address, purchased an old

engine and boiler to enable the firm to be independent of outside power, and

engaged their first workman — Henry Guy, who remained with them for the rest of

his working life. On 17th October, 1857, he was paid thirty-four shillings for

his week’s work of seventy-three hours.

Soon after the move the work on hydraulic jacks proved its value and

importance. Throughout 1857 the imagination of the engineering world had been

caught by the mammoth ship nearing completion under Brunel’s direction on the

mud flats at Miliwall. The size of the vessel had made a broadside launch

necessary, and letters of advice and speculation on methods of launching

appeared regularly in the columns of such journals as the Engineer. By 3rd

November, 1857, the ship was ready and Brunel’s plans were put into action. He

had worked out a scheme of pulling and pushing to assist the gravitational

force which was expected to cancel the friction of the ways; a pull was exerted

from four barges on the river, on each of which was a double crab with treble

purchase blocks, and a push was provided by two hydraulic presses. Brunel’s

calculations appeared to be correct, the Great Eastern was on the move when an

accident to some workmen forced Brunel to apply the braking. arrangements. The

great ship stopped in its tracks having moved only a few feet. By 19th November

Brunel had two more presses, but these, even when augmented by more loaned from

neighbouring shipyards on 3oth November, failed to get the Great Eastern much

nearer to the water. The first week in December, constant pressure having been

applied each day, saw the Great Eastern halfway down the runway. On 17th

December, 1857, Brunel made a progress report before his directors in which he

stated:

‘After

moving the vessel nearly half the distance to low water, it has become

necessary to increase very considerably the power which has effected this much,

although it had already been much added to during the operation.

‘This

will unavoidably be attended with some expense and delay, but not considerable,

as the requisite hydraulic presses can be obtained ready made, and their

application is simple, and the result cannot, I apprehend, be doubtful.’

While Brunel was casting round for more hydraulic jacks he doubtless remembered

James and Joseph Tangye whose work he had seen and admired in William Brunton’s

factory, and whom he must have known to be in Birmingham. Richard Tangye recorded

dramatically in his autobiography how Brunel’s agent came to Mount Street: ‘One

dark evening in the winter of 1856 [Richard’s chronology appears to be at

fault], Brunel’s agent came to our little workshop, which was down an entry

behind a bakers’ shop . and rang the bell. I opened the door; but the gentleman

apologised saying he had made a mistake, and was moving away; but I could not

afford to lose a possible chance of business, and so said “Whose place are you

looking for, sir?” He replied “Tangye’s”. I told him he had come to the right

place, and invited him in, when, having told us his business, he was quickly

reassured upon seeing one of the machines before him. He ordered several of

them, but my brother told him they would not be sufficient to effect the

launch, with which opinion he did not agree.’

Consolidation and expansion were the keynotes of

1858. The brothers first extended their scope in the manufacture of lifting

devices; they were already making hydraulic, screw and bottle jacks, they now

undertook Haley, windlass and traversing jacks. A natural complement to the

jacks were crabs and pulley blocks which they began to make in September 1858.

A few steam engines were constructed during the year for special orders, hand-made throughout.

It is tempting to thinkthat the printers’ press and steam engine on the stocks in the late autumn were

for the old family friend, John Bellows, who was at the time establishing his

own printing works in Gloucester.

It was to Clement Street

in 186o or 1861 that a stranger brought a problem the solution of which was to

prove enormously profitable both to the firm and to the inventor himself. In

1859 Thomas Aldridge Weston, of King’s Norton, nephew of a former mayor of

Birmingham, had taken out a patent for a new and improved pulley block, which

he based on his observation of the Chinese windlass. This device, which was of

considerable antiquity in the East, consisted of a winding drum of two

diameters with a rope lapped round it in opposite directions and a load sheave

carried in the bight of the rope. As the handle of the drum is turned in one

direction the rope is wound on to the larger diameter, and unwound from the

smaller. A powerful lifting effort is generated by this differential effect and

the nearer the diameters of the two parts of the drum the more powerful the

effort.

Weston realised while working on a model of the windlass that by using narrow sheaves

instead of a long drum, by using chain instead of rope, and by joining the ends

together, a simple, compact and powerful piece of equipment would result. To

prevent the chain slipping round the sheaves was the central problem and Weston

eventually designed pockets in the sheaves in which the chain would easily

engage and disengage as the load was raised and lowered. When Weston brought it

to Tangyes the pulley was still in a very crude state and in a small model

only. The top sheave was without flanges which Tangyes added, but although this

prevented the chain jumping out another major difficulty soon presented itself.

The chain failed to run evenly because of the variable size of the chain links,

which were made by the old method of the local chain-makers. A gauge was

therefore constructed from a rectangular iron bar about two feet in length and

properly pitched. By using this mould the chain-maker was able to check each

link and to produce perfectly accurate chain — pitch chain which ran easily in

the sheaves but did not run down when the load was left suspended. George made

the first working model. Weston offered the firm the sole manufacturing rights

in return for a percentage on each one made. Further problems in casting the

sheaves with accurate pockets remained to be solved but nevertheless the pulley

was soon put on the market in a range of sizes, and rapidly created a roaring

trade.

Work on hydraulic machinery continued in the forefront of the firm’s production.

At the 1862 Exhibition, Tangye Brothers and Price also showed their patent

hydraulic cotton and wool press, their improved screw cotton and wool press,

and the patent hydraulic lifting jack. The jack was described as ‘safer than

any hitherto made, inasmuch as the lowering is under perfect control, being

regulated by a screw, the foot and cylinder are also in one forging instead of

being screwed together, or with the claw hung loosely over the head, as is the

case with all other hydraulic jacks’. This jack was made in five sizes, to lift

4, 6, 8, 10 and 12 tons.

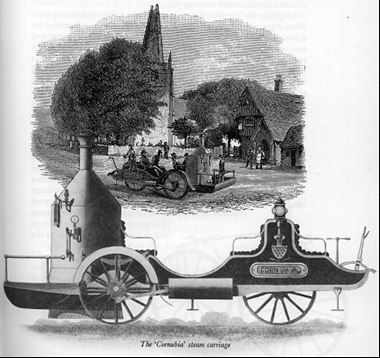

In addition to much hard work and sound achievement, there was an exuberance in

these young days of the firm which produced such jeux d’esprit as steam

carriages and velocipedes. Interest in road steam carriages, widespread in the

earlier years of the century before the advent of railways, revived about 1858.

Several models, including that built for George Salt of Saltaire, were

exhibited at the London Exhibition of 1862. They may well have inspired Tangyes

in the following year to produce the Cornubia. Their declared aim was

not pecuniary profit ‘so much as to provide for themselves and their friends a

pleasurable means of making excursions through romantic parts of the country,

in leisure hours, during the summer months’. Such an idyllic conception of life

with a steam carriage was almost immediately destroyed by the ‘red flag’

legislation of 1865 which prohibited steam vehicles from travelling on the

common roads at a speed above walking pace and unless preceded by a man

carrying a red warning flag.

In the new manufactory the

brothers soon developed two very important lines, steam pumps and steam engines.

Already after seeing it exhibited at the 1862 Exhibition they had taken up the

manufacture of the California

pump, suitable mainly for raising water from wells and for portable fire

engines. This provided valuable experience in pump work.

By 1867 the ‘Special’ Steam pump was

on the market and 400 were sold in the first year. The firm’s 1870 catalogue lists many of

the successful applications of the pump – it was particularly useful in

breweries, paper mills and tanneries. It performed the usual functions of an

efficient pump in draining mines and quarries, for stationary steam fire

engines for mills and factories, and mounted on wheels it could be adapted for

agricultural draining and irrigation. But perhaps it found its most ready

market at this period in the growing demands for gas, water and sewage works

made by Victorian society in the campaign for public health and safety. Like

other Tangye standard lines the pumps were made in a large number of different

sizes and suitable for different needs, all made for and supplied from stock.

The special pump proved a most profitable investment both for Tangyes and for

A. S. Cameron, who received about £35,000 in royalties during the period

covered by the patent.

Soon after the ‘Special’ was successfully launched, George suggested that equal

opportunities existed for the development of compact, simple and standardised

steam engines to perform work on a similar scale to the pump. James set to work

on plans and designs and soon produced his horizontal steam engine. He

concentrated on efficiency, strength of construction, and easy maintenance,

while on the manufacturing side he emphasised the use of interchangeable parts

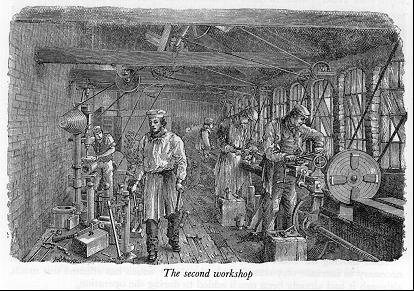

made to standard gauges and jigs. ‘The

fitting shop is of a very convenient design, the lighter tools being all placed

in galleries surrounding and crossing the centre of the building, and supported

on lattice beams. A double hydraulic lift is provided, and in constant action

for the passage of men and materials to and from the galleries. This seems to

us, however, rather an unnecessary development of the saving of labour principles.’

The opening of the ‘seventies saw the end of the partnership. George Price had

already retired in 1869 on account of ill-health. Of the brothers Edward was

the first to leave, deciding to settle in Cornwall

with his ever-increasing family. Gradually James and Joseph found the

repetitive work of the production lines and the large-scale activity at

Cornwall Works somewhat uncongenial. In 1872 an arrangement was made between

Richard and George, who were to continue as Tangye Brothers, and James and

Joseph, who were to retire, but to retain a financial interest in the firm. Not

content to rest on their laurels, Richard and George, during the next decades,

continued to expand home and overseas markets on one hand, and welfare schemes,

engineering enterprise and skill on the other. Their influence was paramount

and continued well into the twentieth century until the death of Richard in

1906 and of George in 1920.

James returned to Illogan, where he purchased Aviary Cottage — a smallish house in a

gentle green valley sheltered from the sea and the mines. There he established

his own workshop in which he could follow the craft which he truly enjoyed. He

spent much of his time giving a free training to young men of the neighbourhood

who wished to prepare for engineering careers, but who, in the prevailing

depression of the Cornish tin industry, had not the means to pay for

apprenticeship. James also fitted up his own observatory with telescope and

sidereal clock so that he could seriously pursue his hobby of astronomy. He

made many journeys back to Smethwick to give

help and advice whenever it was needed, but he never again felt tempted to

leave for long his native village, where he died in 1912.

Certainly a large number of jacks were used for the final launch which began on

5th January, 1858, and was eventually completed on 31st January. George Tangye

later attributed the success of the Tangye jacks partly to the fact that a

number of smaller jacks gave less risk of breakdown than a few larger ones. The

success was also due to a very concentrated period of hard work by James and

Joseph who during the month of November worked extremely long hours, spending a

large proportion of their time on 12-inch cylinder jacks. During the first week

of the month James worked eighty-eight hours and Joseph ninety hours, in the

second week James worked nearly ninety-three hours and Joseph seventy-eight.

They never worked on Sundays, so that this working time was spread over only

six days. The pressure of work continued until the end of the year. Richard

soon afterwards coined the phrase ‘We

launched the Great Eastern, the Great Eastern launched us’. On the whole

the launch of the firm may be reckoned more successful than that of the ship

which, although a magnificent feat of engineering, was a financial loss to all

her proprietors. The use of the jacks on the other hand proved a highly

profitable advertisement for Tangyes, and orders from shipwrights soon began to

stream in.

TANGYE BROTHERS AND PRICE

Work on larger hydraulic presses continued and in November James took out a

patent for a new hydraulic jack. The main improvement, designed to prevent loss of power by

leakage of the liquid, In the ordinary hydraulic press the

cistern or reservoir for holding the water or liquid with which the press is

worked is detached from the said press, and a connection between them effected

by means of a pipe or tube. This improvement in hydraulic presses consists in

making the cistern or reservoir in the base of the press — the said press being

hollow.’

Meanwhile Joseph was able to spend a considerable part of his time on capital

equipment and tools for the workshop itself. A new 10 1/2 inch lathe was built,

and various tools including screwing tackle, taps, an 11-inch chuck and a

drilling machine. With new tools new workers could be taken on — in January

1858, a smith, James Hughes, was employed with his striker, followed by J.

Fewtrell with his son to do the jobbing. Three more workers came in May and a

fitter and turner in July. Altogether the wages bill increased from about £6 in

February to £14 in September. By the end of the year the work justified the

employment of more men and machines, but the tiny workshop was already bursting

at the seams and offered no space for further expansion.

Despite their success, the brothers by themselves could not command sufficient

capital for new premises. A partnership with another Friend, George Price, was

therefore arranged and came into force on 1st January, 1859. James Tangye and

Brothers came to an end; the firm now became Tangye Brothers and Price.

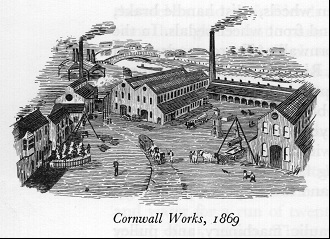

In anticipation of new funds, building had already begun in Clement Street

, off the Parade, and was

completed early in February. All the work inside and fitting out the shops was

carried through by members of the Mount Street workshop, and within a week the

factory was in its new home, bearing for the first time the title of Cornwall

Works. Soon more workers appeared on the books, including two pattern-makers

who remained long with Tangyes:

Alfred Teague, who bore a Cornish name, and George Deakin. The move to Clement Street was

only the first step in the enormously rapid expansion of the works which marked

the ‘sixties and which depended largely upon several excellent patents.

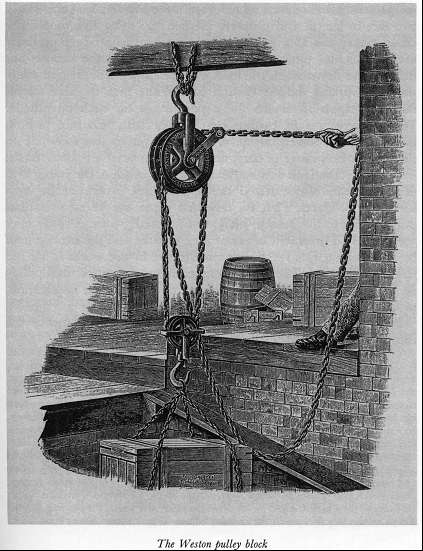

THE WESTON PULLEY BLOCK

In 1862 at the International Exhibition in London, the young firm of Tangye and Price

seized the opportunity to exhibit its most successful products. First on their

list came the Weston’s patent pulley block in five sizes to lift , 1/2, 1, 1

½, 2 and 3 tons. Already over 3,000 sets

had been sold in about nine months and the catalogue of the Exhibition stated ‘they are now in use in the works of all the

leading engineers’. Thomas Weston exhibited the differential pulley on his

own account, and gained a medal for ‘original application, practical utility

and success’.

By 1865 the pulley blocks had been put to miscellaneous use throughout the

world:

‘These blocks, besides their extensive

use in warehouses and manufactories, have found several special applications.

While recovering from his recent illness, the King of the Belgians was

accustomed to ascend from one floor of his palace to another by means of these

blocks, a suspended couch being provided, from which his Majesty, with very

slight exertion, could raise or lower himself at pleasure. In a note to the

inventor, General Garibaldi recommends their use for remounting artillery

thrown down upon the battlefield. The watchman at the lofty fire observatory at

Hodges’ Distillery, in London, raises himself easily and rapidly to a height of 135 feet.

At an Aballoir, near Brussels, 120

pairs are used in hoisting and hanging the carcases of the slaughtered beasts.

Prince Napoleon, in person, purchased a pair at the Battersea Agricultural

Show, for use on board his yacht. In Borneo,

they are attached to trees overhanging the coast, for loading vessels. They are

also largely used in the Cornish Mines. They suspend heavy chandeliers in

public halls, etc. They are fitted on board the Royal Oak and other iron-clad steamers. They

lift the tops off wagonettes in coach-houses. In short, wherever lifts are

required with complete security in raising and lowering, the differential

pulley-blocks are employed with advantage.’

So important was the trade in Weston’s blocks to the firm that within a few

years they found themselves forced to undertake a long and costly Chancery

lawsuit to protect the patent. A remarkable attempt had been made to cast a

pulley block identical with the Weston block by an ironmonger and smith named

Stott. He based his case partly on his forgery and partly on the contention

that an earlier inventor, Moore of Bristol, had produced a pulley block in 1830

embodying the differential principle and using chain. Tangyes found little

difficulty in showing that the methods used by Moore were impracticable, or that the pulley

alleged by the defendants to be eight years old and thus antecedent to the

Weston patent was in fact a recent copy. The Engineer summed up its comment of

the trial on Q9th December, 1865, ‘After evidence showing so clearly that

Weston’s invention resulted in little less than the development of previously

barren ideas — it was not merely a considerable difference, but also as great

an advance on Moore’s apparatus — the issue could scarcely be doubtful. With a

verdict for the plaintiff has thus ended one of the most remarkable patent

trials which has lately occurred, whether we regard the importance of the

issues or the sensational character of one portion of the evidence’.

MORE HYDRAULICS, ROAD VEHICLES AND SOHO

The following year the firm made for the Russian Government a large hydraulic

shearing machine which weighed 24 tons, and was capable of exerting on a

16-inch ram a pressure of 1000 tons — ‘a force sufficient to cut in two a bar

of iron 6 in. square’.

Hydraulic presses were made for such varied uses as stamping palates and

mouth-pieces for dentists’ use, and ejecting a Continuous stream of black-lead

for pencil-making.

Joseph, too, continued to develop his own ideas on hydraulic devices; in 1863

he took Out patents for a portable hydraulic punching machine and for a

portable hydraulic shearing and riveting machine. About the same time he was

working out his multiple screw-Cutting machine which simultaneously produced

six screws for lifting jacks. At first objected to as a threat to the men’s

employment, this machine soon helped to speed up and increase the output of

jacks. A few years later Joseph built a thread-rolling machine to form screw

threads by rolling instead of cutting. Although the idea was not entirely new,

this machine was probably one of the earliest practical applications.

The

Chain and Anchor Testing Act of 1864 created another opportunity for Tangyes.

They were the first to produce really efficient machinery at a reasonable price

for the testing of chain cable and anchors in accordance with the Act. The

Engineer for 22nd February, 1867, commented that ‘the Messrs. Tangye have, in

fact, put down the greater number of the regulation graduated levers required

by the Board of Trade’.

Enquiries for the Cornubia appear to have continued from places abroad and in

the 1870 catalogue the carriages were advertised for £500 complete. The steam

engine at the rear carried sufficient fuel and water for a run of twenty miles

and the vehicle could reach a speed of 25 m.p.h. There was accommodation for

six to eight passengers in addition to the driver at the front, who had ‘full

control of the steam valve and reversing lever, so that the engine can be

started, stopped or reversed by him, as occasion may require, whilst by means

of a very powerful and well-arranged Foot Break [sic] at his command he would

be able to bring the Carriage to a dead stand in an incredibly short time and

distance’. The stoker was of course stationed behind with the engine.

Since the invention of the pedal bicycle or velocipede by the Michaux brothers

in 1861 the new sport of bicycling had gradually become the rage in France.

Several machines were exhibited at the Paris Exhibition of 1867, and soon many firms

were manufacturing versions of the Michaux design. By 1869 Tangyes were

building large numbers at the Cornwall Works, on which they paid royalties to

A. Davis, the London

agent of the French Velocipede Company. The Tangye models were extremely close

to the original pattern, with iron-shod wooden wheels, twist handle brake,

saddle mounted on long leaf spring, and front wheel pedals. In the Museum of

the Royal Institution of Cornwall at Truro stands one of these machines on

which, it is claimed, Richard and George Tangye took the news of the fall of

Sedan (September 1870) from Truro to Newquay. The news itself dealt a severe

blow to the French velocipede industry, and may have caused Tangyes to cease

manufacture for they had important trade connections with France. It is

traditionally told, however, that when Joseph, going far beyond the velocipede,

produced a bicycle with metal wheels and metal spokes, James laid down the law:

‘No more toys’.

Meantime the solid trade in hydraulic machinery and pulley blocks succeeded so

well that the Clement Street

premises soon proved too small and within a few years the firm was looking

round for a new site. The land chosen was outside the borough, on the boundary

of Smethwick and Birmingham, and near the famous

Soho Foundry of which the name had been so familiar in Cornwall. The first lease obtained from

Joseph Gillott was for 7,403 square yards running along the canal where wharves

and bays were soon built for easy loading and unloading. The site was also

conveniently near both the Great Western and the London and North-Western Railway. The plot

was not hemmed in and there was ample space for future extensions. The Clement Street

buildings were retained but the greater part of the work moved to Soho in 1864. Gradually Tangyes have spread across the

adjoining land and here today they still stand now covering 20 acres.

PUMPS AND ENGINES

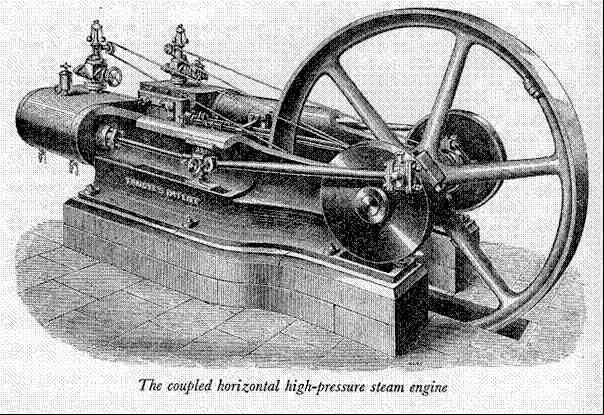

An overhung cylinder replaced the traditional pattern of cylinder, supported

throughout its length by the bed, an arrangement which had made the maintenance

of the steam exhaust pipe difficult. The crosshead was also arranged for easy

maintenance and so that its guide shoes could be easily adjusted to take up

wear. The connecting rod was of pleasing design, swelling in the middle and

tapering at each end which gave the maximum strength where it was most needed.

The simple undecorated design of the whole engine earned the description of the

‘Quaker Engine’. It included a finely proportioned casting for the bed which

carried the slideways for the crosshead guide and was swept over to form the

main bearing for the crankshaft. James also adopted a cast iron disc on the

crankshaft to carry the crank-pin instead of the usual oval or rectangular

member; this gave a very stylish appearance as well as being mechanically

sound.

As a companion to the engine, James designed and patented in June 1869 a new

high-speed governor which combined in one unit the function of governor,

throttle valve and stop valve. Driven at high speed, the governor was very

sensitive and gave more uniform working in the engine; in addition it had the

advantage of being neat and inexpensive. Many thousands of these governors were

sold in addition to those fitted on the horizontal engines.

The engines, like the pumps, were extremely successful and the design itself;

although modified from time to time, once again demonstrated James’ skill as an

engineer, for the main features were retained until the firm stopped making

steam engines shortly before the 1939

war.

Cornwall Works, which specialised in the production of labour- saving

machinery, was naturally to the fore in the use of such devices. An article in

the Engineer of 27th March, 1868, contrasts with the unimproved trade of

lockmaking the manufactory of Messrs. Tangye Brothers at Soho,

and provides incidentally a valuable contemporary picture.

‘In the arrangement of their works no pains have been spared to employ

mechanical appliances for almost every operation that is carried on, and in

some cases we are inclined to think that the principle has been pushed rather

too far, though as we have said in the case of locks, the introduction of

perfect automatic machinery in one branch leads almost necessarily to its

employment in all. Engaged mainly in the manufacture of hydraulic machinery,

Messrs. Tangye have applied the principle in a variety of ways throughout their

works. A pair of pumps standing in the principal fitting shop, and driven by a

separate engine, keep up constant pressure on an accumulator

from which power is taken for working the various cranes, lifts, etc. Amongst

the tools in the fitting shop are three or four lathes, the headstocks of which

carry either two or three face-plates so that, in boring a large number of

cylinders of the same size, either two or three can be chucked side by side and

bored simultaneously. This is the first time we have seen such an adaptation on

an ordinary lathe, and believe it to have originated with Messrs. Tangye

END OF THE PARTNERSHIP

Joseph retired to Tickenhill Manor at Bewdley, an ancient spot poised

high above the town and the river. He too soon set up his workshop where he was

free to follow his own bent and to practise his fine craftsmanship. It was here

that he designed and built probably his finest precision instrument — a

measuring machine accurate to a hundred-thousandth part of an inch. This he

presented in June 1384 to

the Corporation of Birmingham and it is now exhibited in their Weights and

Measures Department. Here, too, in the earliest days of electric light he made

his own dynamo and lighted the room for the pleasure of visitors. Joseph also

took an active interest in local affairs in Bewdley and set himself to improve

for the inhabitants such amenities as gas and water supplies. Near Tickenhill

Manor he later built a new house, Hem’s Nest, which he occupied until his death

in 1902.